Contacts: F. Arefi-Khonsari, J. Pulpytel

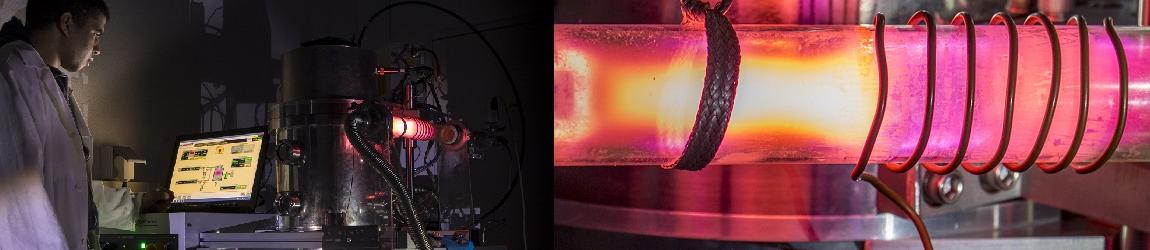

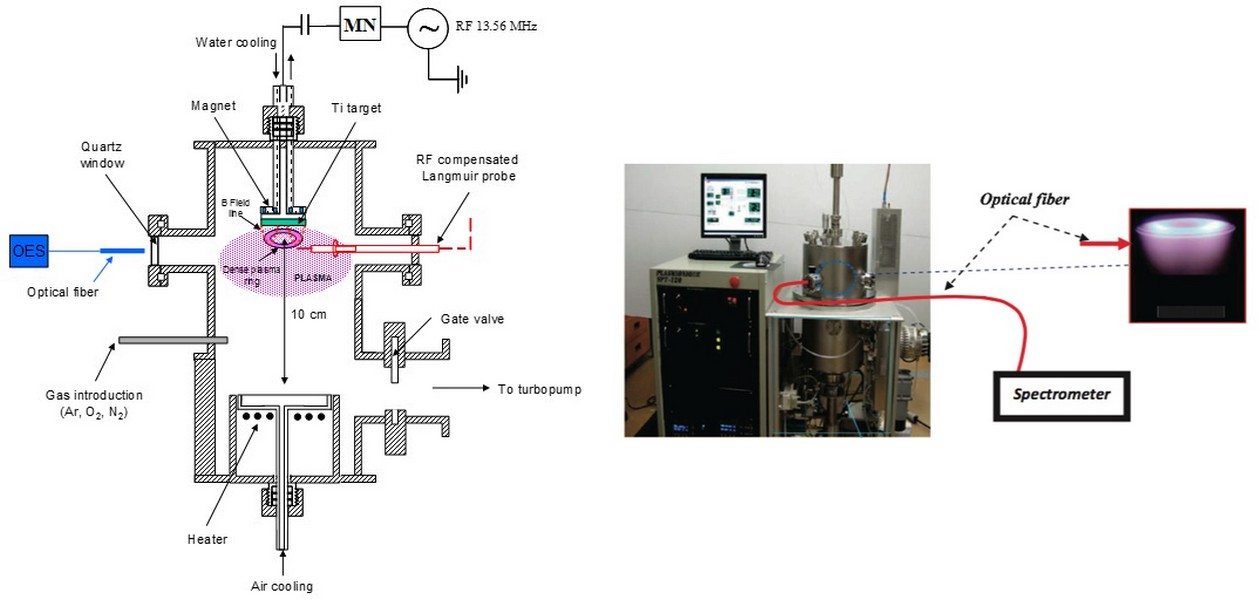

- Magnetron sputtering system :

Sputtering is a widely used physical vapor deposition technique for the deposition of a wide range of thin coatings used also in an industrial scale on various substrates for numerous applications. The basic sputtering process consists of removing i.e. sputtering the target or the cathode by means of bombardment with energetic ions generated in a glow discharge plasma. The sputtered atoms will then condense on the substrate to form the thin films. As a result of the ion bombardment, secondary electrons are also emitted from the cathode which play an important role in maintaining the plasma. In magnetron sputtering a magnetic field is applied parallel to the electrode by means of two magnets, arranged at the central axis and outer edge of the target. The magnetic field traps the secondary electrons and constrains their motion to the vicinity of the target and will considerably increase the probability of ionizing collisions, resulting in higher deposition rates at the substrate. The sputtering system at LISE is a balanced magnetron sputtering commercialized by Plasmionique in Canada (SPT120, RF :13.56 MHz, MAGNION-B) The pumping system is composed of a turbomolecular (300 L/s, Varian TV301 Navigator) and a mechanical one (ULVAC). Our system is equipped with two cathode magnetrons, 2 inches of diameter, as well as an optical emission spectrometer (OES) which allows the possibility to identify and follow the excited species in the discharge and in this way to monitor the stoichiometry of the deposited thin coatings

2- PECVD(plasma enhanced chemical vapor deposition) system at low pressure for the deposition of thin organic layers.

The PECVD process allows to deposit different organic and inorganic coatings from a wide range of precursor vapors on different substrates. The glow discharge at low pressure initiates the formation of radicals which is a unique technique to deposit a wide range of plasma polymers by a dry process without the need to use a catalyst. Dense homogeneous coatings can be deposited in the continuous wave mode (CW)or the pulsed wave mode(PW) . LISE is equipped with a inductively coupled plasma(ICP) provided by Plasmionique(FLR300-H).This type of system is characterized by a high electron density. The system offers the possibility to introduce two precursor vapors at the same time to deposit copolymers.