Contacts : François Huet and Kieu Ngo

The electrochemical noise technique is used for studying the random behaviour of electrochemical interfaces.

In this approach, all quantities characterizing the state of a metal/electrolyte system:

- electrode potential,

- concentration of the reactive species,

- temperature of the interface,

- active surface of the electrode,

- electrolyte velocity...

are fluctuating quantities. These spontaneous fluctuations provoke fluctuations of electrical quantities that can be measured (current noise for an electrode under potential control, potential noise for an electrode under current control), which are commonly termed electrochemical noise (EN).

EN measurements are very informative for systems in which the elementary events at the origin of EN are at a semi-macroscopic scale; they often involve a dispersed phase (gaseous, liquid or solid) in the electrolyte. Only EN allows characterization of the kinetic behaviour of these elementary events:

- growth and detachment of a bubble on a gas-evolving electrode,

- depassivation and repassivation of a passive electrode,

- particle-particle contacts or particle-electrode contacts in a reactor with circulating particles,

- eddies in hydrodynamic turbulent flows...

since the deterministic kinetic techniques commonly used (polarisation curves, electrochemical impedance) give information averaged in time and over the electrode surface.

In order to have access to the various fluctuating quantities (active surface, concentrations...), a new technique has been devised in the laboratory. It consists in simultaneously measuring the EN and the fluctuations of the electrolyte resistance (electrode high-frequency impedance) ΔRe(t), which expresses the variations of the primary current distribution around the electrode and then do not depend on the interfacial electrochemical reactions. Under current control, the potential fluctuations ΔV(t) can be written:

ΔV(t) = ΔE(t) + ΔRe(t) I

where ΔE(t) represents the fluctuations of the faradaic potential.

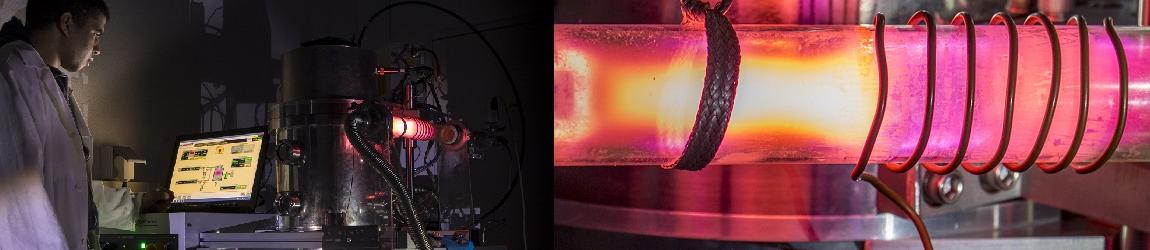

EN is commonly analysed in the time domain from the time records of the fluctuations (see figure 1), and in the frequency domain from the power spectral density (PSD or spectrum, see figure 2) of the fluctuations that represents the distribution over frequency of the power of the random signals measured.

As examples:

- the variations of the electrolyte resistance ΔRe of a gas-evolving electrode depend only on the variations of the electrode active surface caused by screening effects and their analysis allows estimation of the bubble mean size, bubble-size distribution, bubble detachment mean rate... whereas the variations of the faradaic potential depend on both variations of active surface and dissolved-gas concentration.

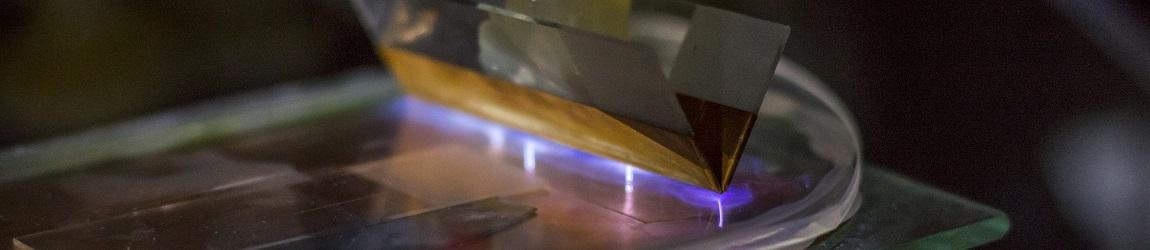

Figure 1: Time records of the potential and electrolyte-resistance fluctuations caused by hydrogen-bubble detachments on an iron disk electrode (diameter 5 mm) at the corrosion potential in H2SO4 1M. - for an electrolyser with metallic particles circulating in the electrolyte, the EN analysis first allows valuable information on the dynamics of the particles circulating close to the electrode (mean rate of passages, velocity, approaching time, residence time close to the electrode, trajectory...) to be obtained, and second informs on the charge transfer on the particles impinging the electrode (percentage of impinging particles, mean charge exchanged, time constant of electrode recharge). For an oil-brine mixture, the EN analysis gives information on the composition of the mixture close to the electrode and on the hydrodynamic flow pattern.

Figure 2: PSDs of the electrolyte resistance fluctuations for a mild steel RDE at the corrosion potential in 3 wt % NaCl with paraffin oil at different volumetric ratio.

Since the appearance a few years ago of electrochemical cells with two working electrodes connected through a zero-resistance ammeter (ZRA) (see figure 3), EN measurements are widespread in the corrosion domain since both potential and current fluctuations generated by corrosion processes can be measured at the corrosion potential, which allows the noise resistance, which is related to the corrosion rate of the metal, to be derived and monitored with time with low-cost instrumentation. The frequency-domain analysis also permits the impedance modulus of the electrodes to be measured from the noise impedance, without requirement of external perturbation signal, the internal noise caused by corrosion acting as excitation signal.

Figure 3: Experimental arrangement used for simultaneous measurements of EPN and ECN at the corrosion potential (Gv and GZRA: gains of the voltage amplifier and ZRA, LPF: low-pass filter)

Reference: F. Huet, “The electrochemical noise technique”, in “Analytical Methods in Corrosion Science and Engineering”, eds. P. Marcus and F.Mansfeld, Taylor & Francis, CRC Press, Series: Corrosion Technology, Volume 22, p. 507-570 (2006).