Contact : Florence Billon

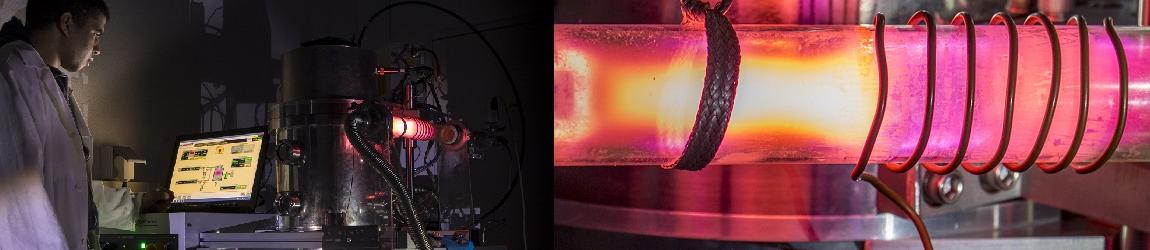

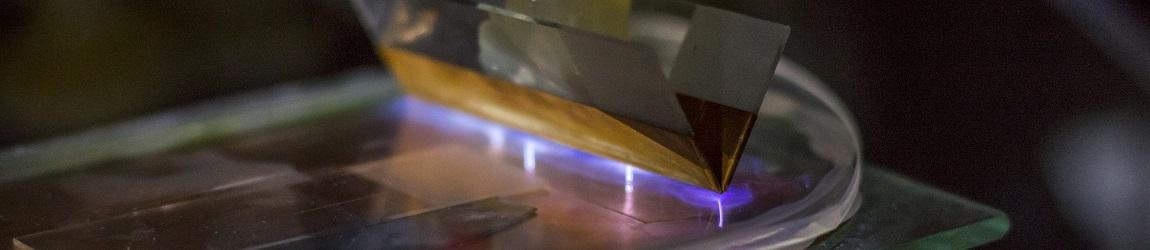

Thin films of amorphous carbon nitride a-CNx (PLASSYS MP300S)

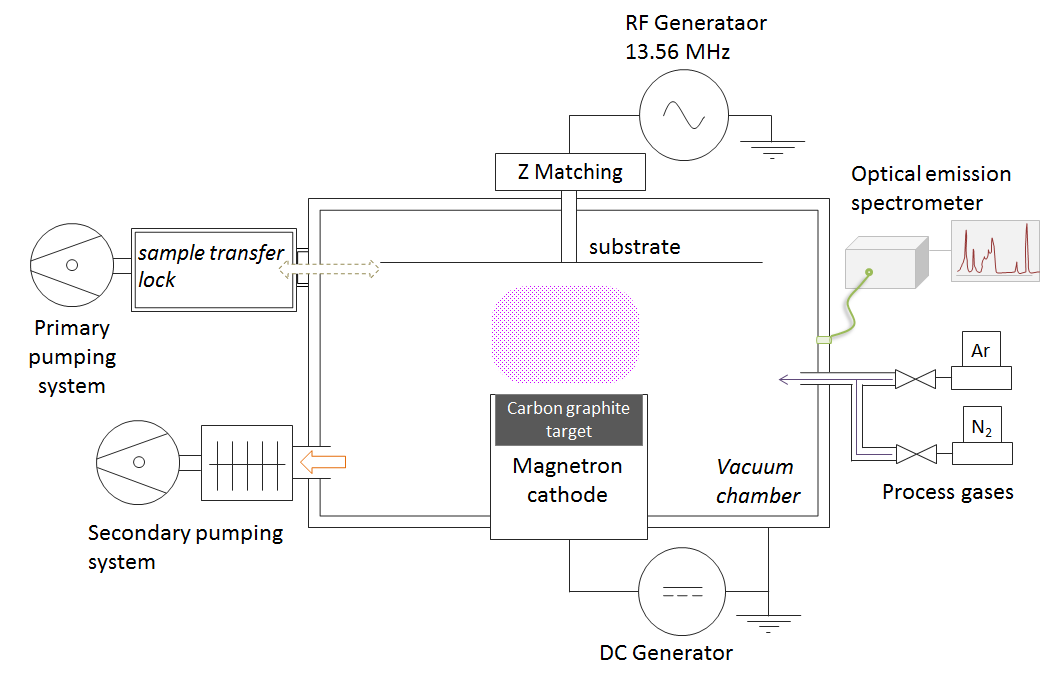

PLASSYS MP300S is a DC magnetron sputtering deposition system.

It includes a deposition chamber equipped with an airlock for the transfer of samples without breaking the vacuum (reduced pumping time before deposit and better vacuum quality).

The Plassys MP300S deposit chamber is entirely dedicated to the production of carbon-based thin films and more specifically to amorphous carbon nitride films a-CNx. This gives us a better control of the quality of the layers deposited (limitation of the impurities). Indeed this type of layer has demonstrated interesting properties for the fabrication of active electrodes over a wide range of potential.

Characteristics

- Deposition technique: DC magnetron sputtering

- Graphite carbon target: purity 99.999%, surface 44 cm2

- Substrates: all types, maximum size 6 cm (homogeneity: about 2-3 cm)

- Polarization of the substrate holder: RF ion etching of the substrate (improving films adhesion)

- Ultimate vacuum: about 5.10-8 Torr (with a turbomolecular pump)

- Gas: Ar and N2

- Sample transfer lock

- PlasCalc optical emission spectrometer: study of plasma gas

Properties of a-CNx films

- Amorphous materials almost free of hydrogen

- The composition of the films (Csp3 / Csp2) and therefore their properties (conductivity, electrochemical reactivity, etc.) vary according to the deposition conditions

- The film follows the topography of the substrates

- Chemically stable

- Mechanical property close to that of diamond

- High compressive internal stress

Examples of use

- New electrode materials (interesting properties for electrochemistry)

- Conductive Amorphous Carbon Deposition (undoped)

- Microsystem

- Materials for photovoltaics

- ...

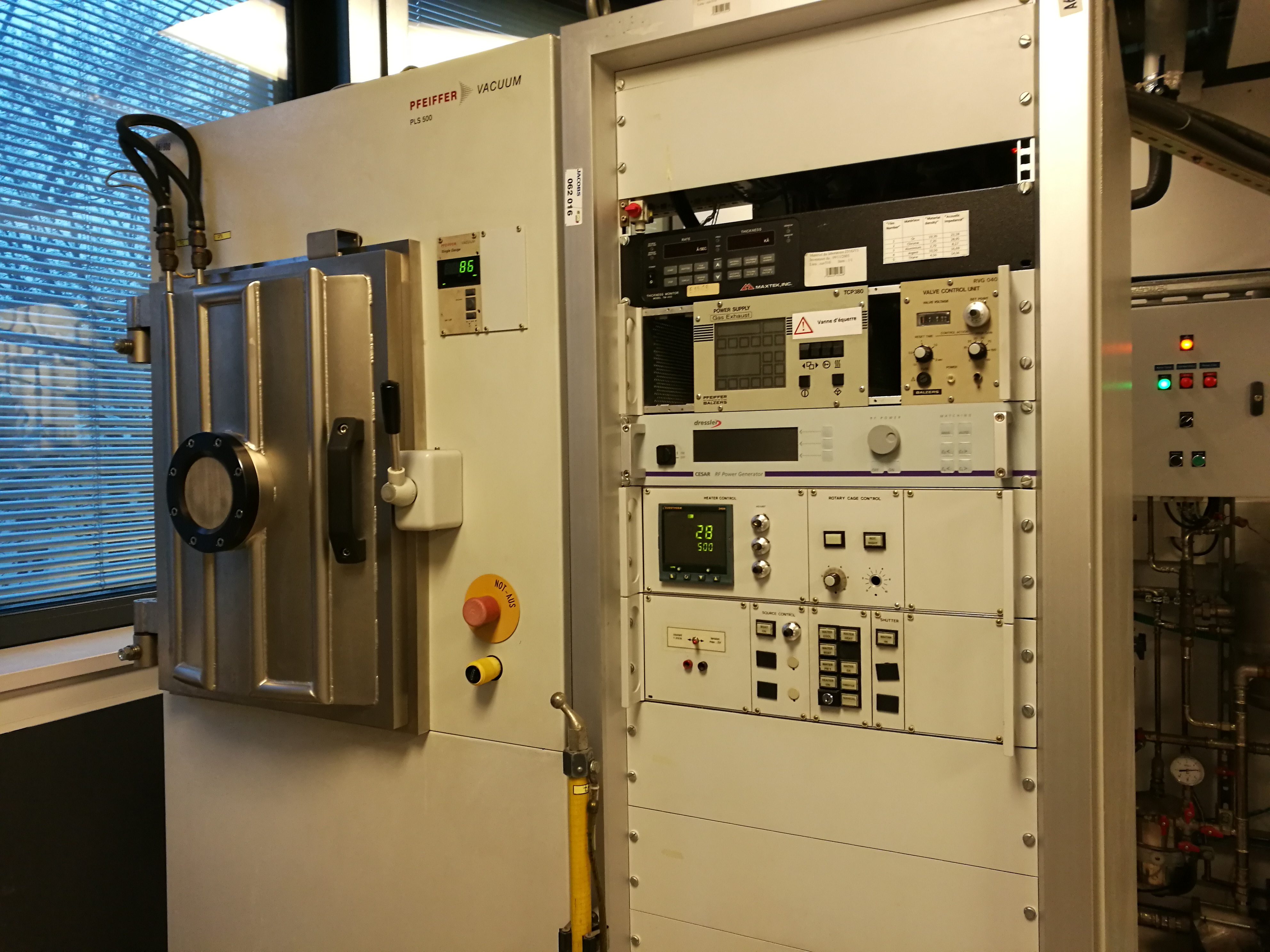

Metallic thin films (PFEIFFER PLS 500)

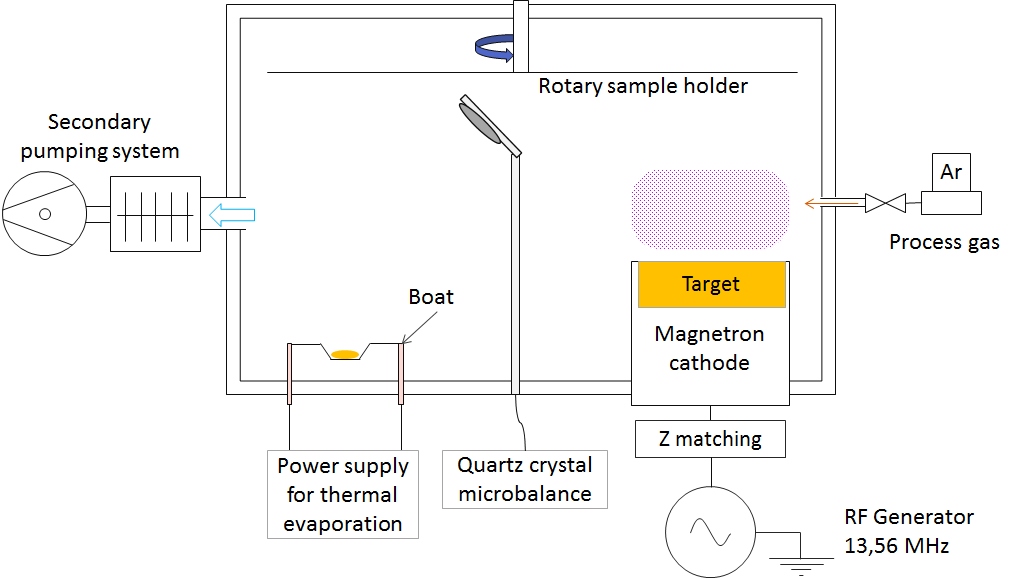

The Pfeiffer PLS 500 machine allows vacuum deposition of thin metal layers using two vacuum deposition techniques:

- radiofrequency magnetron sputtering

- vacuum evaporation

The rotating substrate holder allows the production of multilayers by combining both techniques.

Characteristics

• Deposition techniques: RF magnetron sputtering and vacuum thermal evaporation

• Ultimate vacuum: about 2.10-7 mbar (with a turbomolecular pump)

• Heating substrates up to 450°C (halogen lamp system)

• Rotating substrate holder: possibility to make multilayer by combining the 2 deposition techniques

Example: thermal evaporation of a Cr bonding layer (5-10 nm) + gold sputtered thin film

RF magnetron sputtering

- Targets: metals (Au, Cu, Cr, Ti, Al, Pt, Fe ...) / diameter 51 mm

- Gas: only Argon available

Vacuum thermal evaporation

• Evaporation sources: mainly W boat heaters

• Monitoring of thickness and deposition rate with a Maxtek quartz microbalance

• Metals: Au, Cr, Ti, Ag, Cu ...

Examples of use: .

- Manufacture of electrodes

- Conductive layers

- Quartz resonators coating

- SERS Substrates

- ...